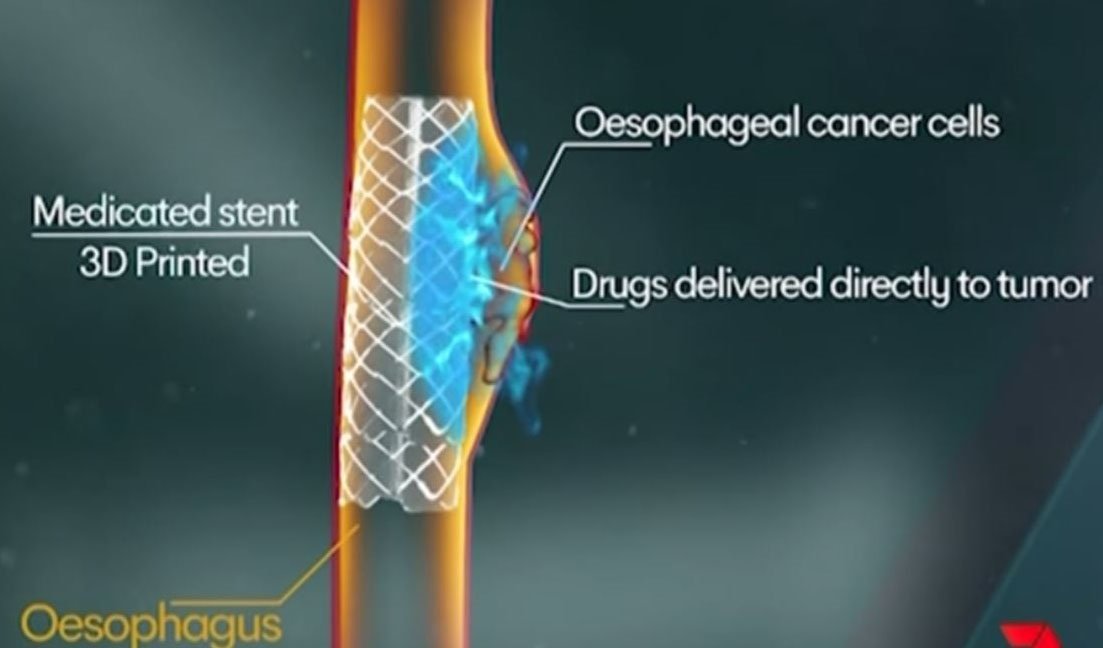

Fabricated from polyurethane filament and incorporating the chemotherapy drug, 3D printed stents deliver breakthrough treatment for oesophageal cancer

World-first 3D printed oesophageal stents developed by the University of South Australia could revolutionize the delivery of chemotherapy drugs to provide more accurate, effective and personalized treatment for patients with oesophageal cancer.

Fabricated from polyurethane filament and incorporating the chemotherapy drug 5-fluorouracil (5-FU), the new oesophageal stents are the first to contain active pharmaceutical ingredients within their matrix. Their unique composition allows them to deliver up to 110 days of a sustained anti-cancer medication directly to the cancer site, restricting further tumour growth. Importantly, the capabilities of 3D printing enabling rapid creation of individually tailored stents with patient-specific geometries and drug dosages.

PhD scholar, UniSA’s Paris Fouladian, says the new oesophageal stents could be a gamechanger for treating oesophageal cancer.

“The most prominent symptom in Oesophageal cancer is dysphagia (difficulty swallowing food or drink) which is due to malignant cancer cells blocking the oesophagus. Blockages are commonly eased by an oesophageal stent – a small tube that is placed in the food pipe to keep it open – but these too can become obstructed by invading cancer cells. Our new drug-loaded oesophageal stents can help prevent further blockages by administering anti-cancer drugs directly to the tumour, limiting further growth while relieving the pressure of dysphagia,” says the scholar.

The new drug-loaded 3D printed oesophageal stents are stable to both UV and gamma sterilization processes. Senior researcher and Director of UniSA’s Pharmaceutical Innovation and Development Group, Professor Sanjay Garg, says the new technology is a significant breakthrough in modern drug delivery.

“3D printing processes that combine medicines and medical devices are on the precipice of changing the way we deliver medicines. We’re now exploring the potential of 3D printing to design precise and individualized drug delivery systems,” Prof Garg says.