Key to life sciences - The complex relationship between enzymes and substrates

Enzymes are seen as the major drug targets and are also being used as molecular machineries in the production of drug. Therefore, the understanding of enzyme-substrate (E-S) relationship is critical for both drug discovery, development and in their production.

Enzymes are seen as the major drug targets and are also being used as molecular machineries in the production of drug. Therefore, the understanding of enzyme-substrate (E-S) relationship is critical for both drug discovery, development and in their production.

For a required enzymatic activity, the enzyme-substrate (E-S) relationship is the most important determinant of an E-S reaction. This relationship determines the kinetics and the thermodynamics of the reaction at different process conditions both at the lab and the industrial scale.

The understanding of E-S reaction and its relationship at different process conditions, behavior at different pH, temperature and solvents, can provide important insights for designing enzymes, substrates and inhibitors for a desired reaction. Some of the desired enzymatic reactions, include enhanced thermal and pH stability, enhanced turnover number, enhanced substrate specificity and many more attributes. In order to precisely attain these physical and thermodynamic parameters, the R&D groups within the company employs rational redesign or a directed evolution approach to study the enzyme and enhance its properties by employing traditional polymerase chain reaction (PCR)-based mutagenesis.

While in silico approaches like protein modeling, QSAR, docking and molecular dynamics are adopted during this process to design enzymes and substrates, these tools are not customized to mimic those protocols in a rational redesign or a directed evolution study of enzymes.

However, there is a possibility of exploiting computational methods to engineer the enzymes and enhance their productivity in a systematic way. This in silico framework for enzyme engineering is a step beyond the structure-based virtual screening system for drug discovery. The output of the analysis, like the catalytic reaction coordinates of E-S reaction, predicted activation energy and the rate limiting steps of the reaction can be used to design excellent substrates and inhibitors.

Here we describe a short study of how our in silico framework for enzyme engineering (eEF) can be applied to model and study the catalytic reaction coordinates of E-S reaction, identify hot spots in enzymes, generate more than a hundred thousand mutations, filter for the most appropriate E-S mutations and simulate E-S reaction to predict the kinetics, activation energies and rate limiting steps of the potential enzyme mutants.

The challenge undertaken was to engineer enzymes involved in the production of beta-lactam antibiotics. With annual sales of around $15 billion worth of penicillins and cephalosporins constituting close to 65 percent of the total antibiotics market [1], beta-Lactam antibiotics alone constitute most of the world's antibiotic sales (30 million kg/year out of a total 50 million kg/year produced worldwide [2]). There are battery of potential synthetic beta-lactam antibiotics produced using the chemical process, which in turn can be synthesized using the same enzyme that produce natural substrates like penicillins and cephalosporins. Moreover, enzyme-mediated conversion of beta-lactam antibiotics provides a novel direction for antibiotics industries and promotes a safer and cleaner environment [3] but this requires small or large transformations of these enzymes. The need to improve the present enzymatic reaction towards the natural substrates and attain activity for the synthetic substrates is set as foremost priority of enzyme engineering framework (eEF).

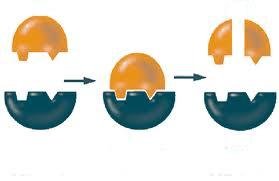

The mutagenesis carried out using eEF are based on the substrate binding path that is obtained from the kinetic pathway of the substrate/inhibitor diffusing from solvent to the bound state passing through different intermediate states. Rather than directly entering the binding pocket, the substrate/inhibitor appears to move on the surface of the enzyme in its transition states and then finally enter the catalytic site [4] (as shown in the Figure below).

This way the framework helps in identifying new hotspots that maybe missed out during a conventional enzyme engineering procedure. To identify hotspots in the enzyme we use different sampling techniques and the resultant trajectories are used to calculate inter-atomic weights for the residues in-and-around the active site. These weights are based on the physical contact and contact energies like Van der Waals forces, electrostatic, hydrogen bonds energies, pi-pi and cat-pi energies. Also, during the simulation process, we explore the path taken by the active substrates (high and low activity), inactive substrates (no activity) and substrates of interest to enter the active site of the enzyme. This way it helps in identifying modification sites even away from the binding site (identify new modification). This information is critical to engineer the enzyme, which will facilitate the substrate entry to the active site and the product dissociation forms the active site there by optimizing the whole enzymatic reaction.

Apart from this, transformations of desolvation parameters and intra hydrogen bond energies are analyzed to compute the stability of the proteins. The filtered modifications enter the next level in the framework called 'the transition state analysis', which generates reaction coordinates of different stages of transition states like E-S transition state, E-Sïƒ E-P transition state and the E+P transition state. This is done using techniques like quantum mechanics/molecular mechanics (QM/MM) simulations, steered molecular dynamics and transition path sampling. Finally, the transition state reaction coordinates are used to predict the kinetic properties, activation energy and rate limiting steps of the mutant enzymes.

For example, we successfully identified the pressure points (as indicated in the graph below), which are the local energy barriers across the enzyme that lead to an un-catalyzed reaction. This information narrows down the hotpots for mutagenesis, a key step towards engineering the enzyme to produce a synthetic beta-lactam based antibiotic.

Moreover, E-S reaction coordinates during the transition state analysis reveal the crucial active site residues (as shown in the figure below) that are involved in substrate product conversion and product dissociation.

There is a consensus across industries that many biologically available enzymes have a great potential to be exploited if they can be productive at reasonable physical conditions.

There is a consensus across industries that many biologically available enzymes have a great potential to be exploited if they can be productive at reasonable physical conditions.

However, their inherent thermodynamics calls for higher investment in the production process leading to the final high cost to the end-consumer and the constant quest to optimize the enzyme by engineering it for suitable is driving the R&D of many well known successful biotechnology and biopharmaceutical companies. We hope that our in silico framework can significantly contribute to the both the industry as well as the end-consumer.

.................................................................

References:

1. Elander RP; Industrial production of beta-lactam antibiotics; Appl Microbiol Biotechnol 2003; 61:385-92

2. DeSouza VR, SilvaACG, Pinotti LM, Ara´ujo HSS, Giordano DLMC; Characterization of the penicillin G acylase from Bacillus megaterium ATCC 14945; Braz Arch Biol Technol 2005; 48:105-11

3. Arroyo M, De la Mata I, Acebal C, Castillon PM; Biotechnological applications of penicillin acylases: state of the art; Appl Microbiol Biotechnol 2003; 60:507-14

4. Ignasi Buch, Toni Giorgino, and Gianni De Fabritiis; Complete reconstruction of an enzyme-inhibitor binding process by molecular dynamics simulations; PNAS 2011; Doi:10.1073/pnas.1103547108