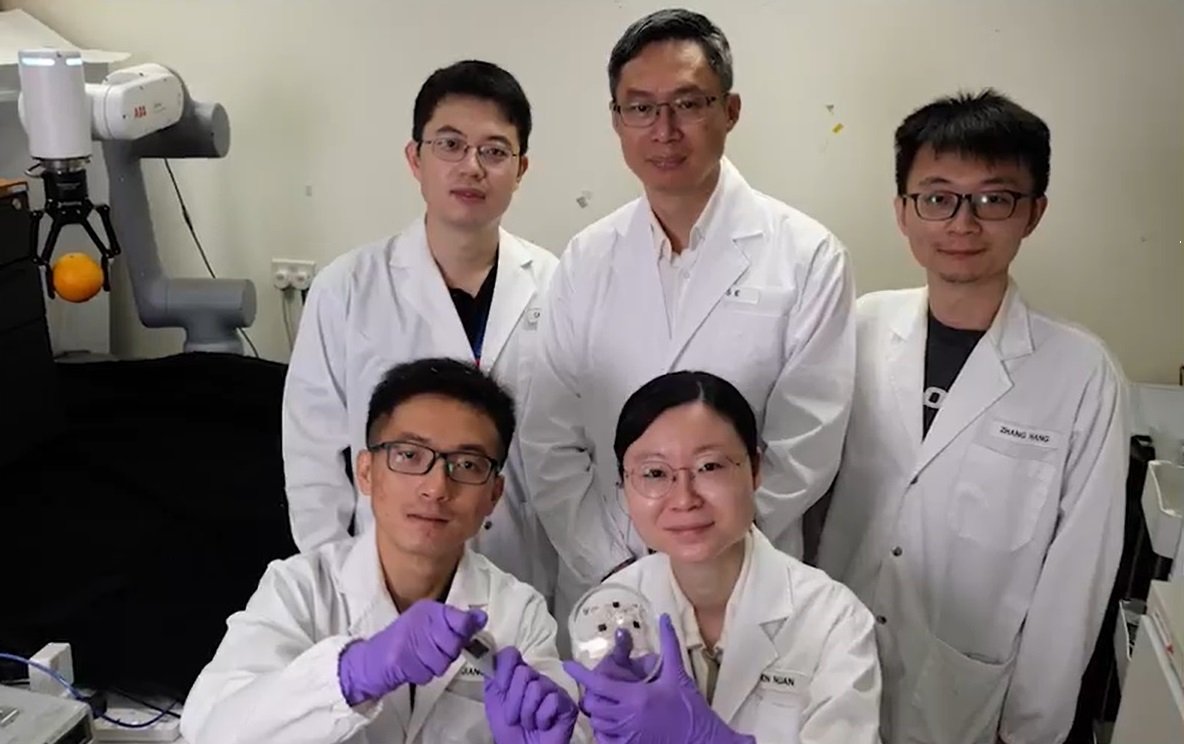

Photo Credit: NTU Singapore

The Nanyang Technological University, Singapore (NTU Singapore) has established a high-tech pilot laboratory capable of rapid prototyping of ultrathin and stretchable electronics that can detect bioelectric signals from skin, muscles and organs, and eventually transmit these signals to control robots or other electronic devices.

The team lead by Prof Xiaodong Chen, President's Chair Professor in Materials Science and Engineering and the Director of the Innovative Centre for Flexible Devices (iFLEX) has developed the invention with his team of pioneering material scientists. NTU Professor Chen Xiaodong has been a trailblazer in soft electronics over the last decade and has his name in over 50 patents.

Revolution in Medtech Industry

Soft electronics use a soft platform – such as hydrogels or biocompatible plastics that are stretchable and flexible, of which NTU material scientists have invented numerous formulations. To enable electronic circuits to accommodate movement without breaking under repeated stress, these circuits are printed on soft substrates using intricate patterns at the micro and nanoscale, about 10 times thinner than the width of human hair.

NTU researchers developed these innovative soft electronics devices by combining in-house designed soft materials and processes with commercially available hardware components. This hybrid combination allows the NTU team to integrate many types of sensors on the market, such as wireless connectivity, accelerometer, temperature sensing, and monitoring vitals like heart rate, blood pressure, oxygen levels, and more. The resulting sensors, encased in a gel-like skin, are soft, flexible and stretchable, similar to silicon bandages used in healthcare. These sensors adhere to the skin, enable joint movement, and come in various sizes and thicknesses, ranging from centimetres to sub-microns – thinner than the width of a human hair (0.01 millimetres).

When these smart sensors are attached to limbs or the head, they empower individuals with limb disabilities or mobility impairments by providing an accessible method to control robotic prostheses, machinery, and motorised wheelchairs using alternative muscle movements and bio-signals.

For instance, a wearable sensor can offer an accessible control method for individuals with limb disabilities or mobility impairments. By attaching these sensors to various parts of the body, users can command robotic prostheses, machinery, and motorised wheelchairs through alternative muscle movements and bio-signals. A study reports that, this healthcare application will impact some 15% of the global population who are living with some form of disability.

Designing High-tech Pilot Laboratory and Industry collaberations

To kickstart the scaling-up process, and to enable rapid prototyping of ultrathin and stretchable electronics, Prof Chen has established a new high-tech pilot laboratory, which aims to collaborate with industry partners to turn their ideas into actual wearables. These thin and flexible control device are just one of many applications that soft electronics can have.

The pilot laboratory aims to co-develop and produce soft electronic devices with industry partners, including Small and Medium Enterprises (SMEs). Through joint projects, Prof Chen and Team hopes to establish industry standards that will facilitate the mass production of soft electronics in the future and develop the necessary expertise for this emerging industry.

National Research Foundation, Singapore (NRF), Agency for Science, Technology and Research (A*STAR), and NTU, are supporting this and many more promising technologies with impactful practical applications.

Another invention of Prof Chen includes a recent breakthrough of “Novel biocompatible material” that can readily shrink and wrap around soft tissues like the heart in response to moisture. The developed materials achieved conformity and flexibility that enables real-time heart monitoring and reduces the risk of implant rejections. The technology can also help pave the way for newer types of better pacemakers and bio-monitors in future.

Moreover, NTU Innovation and Entrepreneurship initiative innvolving NTU 2025 five-year strategic plan, aims to accelerate the transition from research to commercialisation for faculty and students, providing mentorship and industry insights.