Singapore – Esco Aster, a contract development and manufacturing organization (CDMO) of Esco Group, announced the launch of lentiviral vector platform and bioproduction technologies to support the Chimeric Antigen Receptor Therapy (CAR-T) pipeline in China.

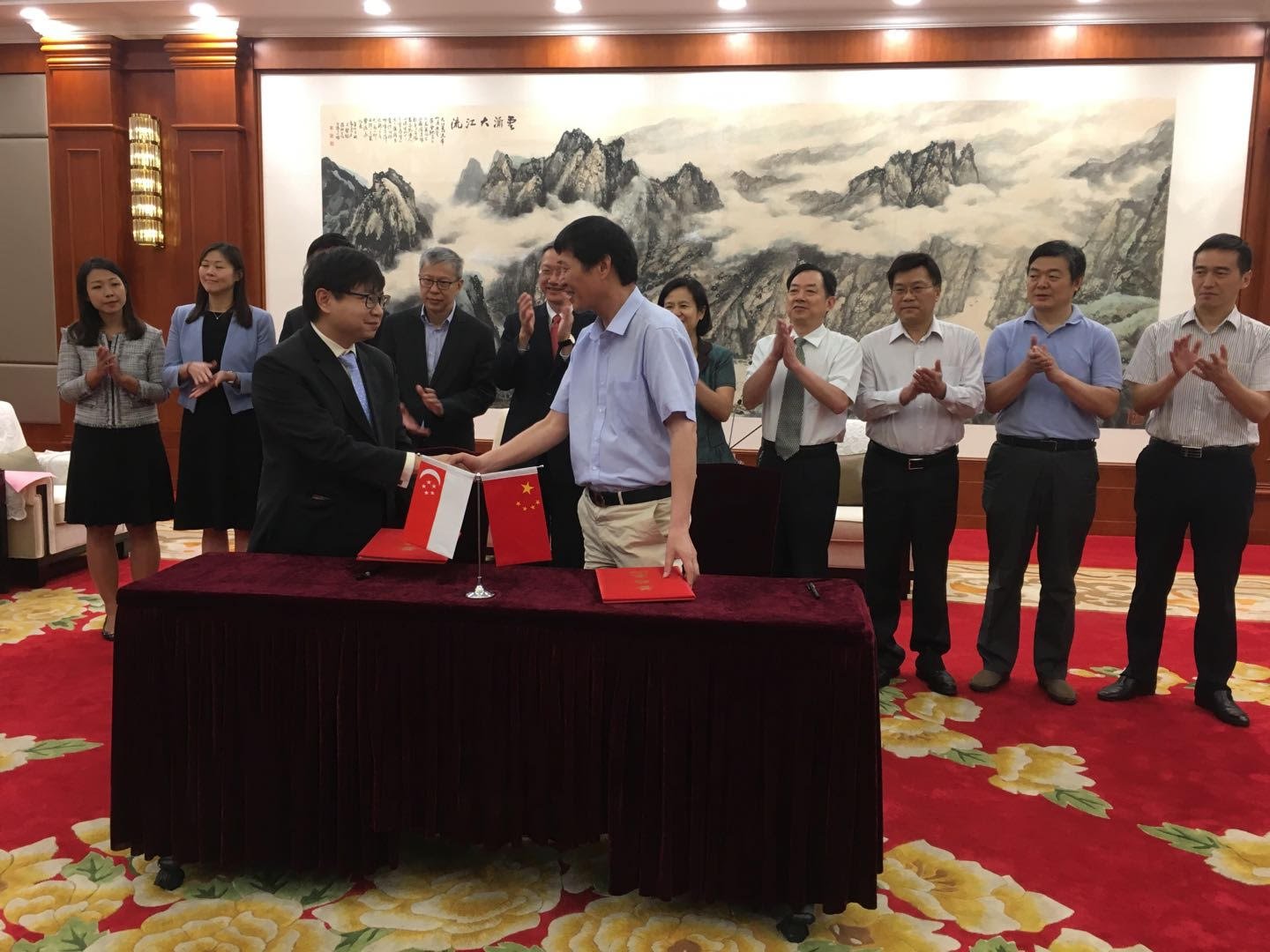

Through an international collaboration, Esco Aster has launched the lentivirus platform and bioproduction technologies in Wuhan Bio-Raid Biotechnology’s large state-of-art manufacturing cGMP facility, and the MoU signing was witnessed by Mr. Sam Tan, Singapore Minister of State for Foreign Affairs & Ministry of Social and Family Development, during his courtesy call on the Wuhan municipal leaders.

“We are very pleased and excited to enter into this strategic partnership with Wuhan Bio-raid Biotechnology, one of the prominent players in CAR-T therapies in China. This partnership,results from the purchase of Esco’s Biological Safety Cabinet,is a strong motivation for entering a win-win collaboration with this highly dynamic company, ” said Mr. Xiangliang Lin, Esco Aster, Chief Executive Officer.

To meet Chinese market’s demand for lentiviral vector (LVV) needed for CAR-T clinical trials, Esco Aster aims to support CAR-T pipelines from discovery to delivery through cGMP production. Their expansion to the emerging CAR-T field is built upon a history of success in the commercialisation of Tide Motion bioreactors.

Esco Aster has successfully applied a process-intensive novel seed-train cell culture strategy using adherent HEK 293T cells. Vials from a high-density cell bank are used for direct seeding into a single-use CelCradle bioreactor to generate adequate cell numbers needed for LVV production in TideCell. This process-intensive seed train strategy as opposed to conventional seed trains, provides a smaller working footprint, time-, cost- and manpower-effectiveness. Such an implementation and improvement can vastly increase the productivity of current LVV cell culture manufacturing facilities.