Unlike traditional printed circuit boards, which are flat, 3D circuitry enables components to be stacked and integrated vertically, dramatically reducing the footprint required for devices.

Advancing the frontiers of 3D printed circuits, a team of researchers from the National University of Singapore (NUS) has developed a state-of-the-art technique, known as tension-driven CHARM3D, to fabricate three-dimensional (3D), self-healing electronic circuits. This new technique enables the 3D printing of free-standing metallic structures without requiring support materials and external pressure.

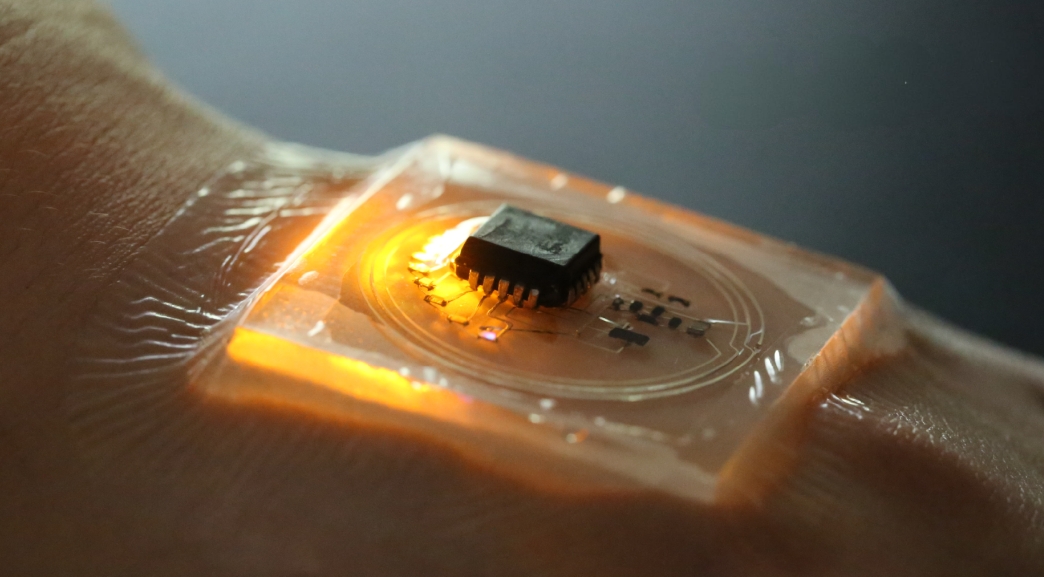

The research team from the Department of Materials Science and Engineering in the NUS College of Design and Engineering used Field’s metal to demonstrate how CHARM3D can fabricate a wide range of electronics, allowing for more compact designs in devices such as wearable sensors, wireless communication systems and electromagnetic metamaterials.

In healthcare, for instance, CHARM3D facilitates the development of contactless vital sign monitoring devices, enhancing patient comfort while enabling continuous monitoring. In signal sensing, it optimises the performance of 3D antennas, leading to improved communication systems, more accurate medical imaging and robust security applications.

Through CHARM3D, contact-free sensors can be integrated into smart clothing and antennas, providing continuous, accurate health monitoring in hospitals, assisted-living facilities or home settings.

The research team envisions that this technique can be extended to other types of metals and structural applications. The team is also looking for opportunities to commercialise this unique approach for metal printing.