Scientists at Nanyang Technological University (NTU), Singapore have developed an innovative wearable fabric that is flexible but can stiffen on demand. Developed through a combination of geometric design, 3D printing, and robotic control, the new technology, RoboFabric, can quickly be made into medical devices or soft robotics, such as limbs for drones.

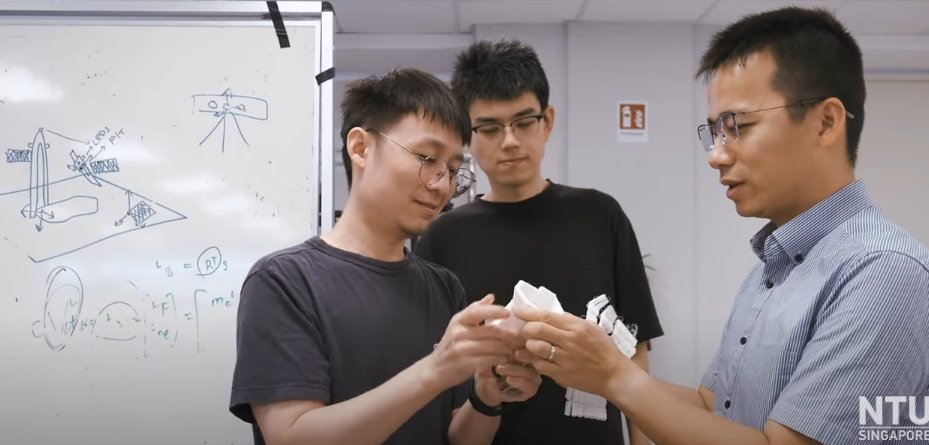

The NTU research team has developed an elbow support from the versatile material, helping people carry heavier loads. A wrist support prototype has also been made, which could help stabilise joints for daily activities and benefit patients with Parkinson's Disease who experience trembling.

Inspired by the scales of pangolins and armadillos which interlock to form a protective shell, the first step in making the patent-pending technology is an advanced mathematical algorithm that designs an interlocking system of tiles. The 3D printed tiles are then joined together by metal fibres running through tiny channels between them, or by an external soft case, which requires negative air pressure or vacuum to be applied constantly.

The team is exploring collaborations with industry partners who have expressed interest in the technology and are hoping to partner with them for deployment trials in the healthcare and robotics sectors, as this made-in-Singapore technology offers new solutions for medical support and enhances the functionality of drones or exploration robots.