Preparedness of pharma supply chains to manage the production of COVID-19 therapies

21 August 2020 | Opinion

In conversation with Rahul Dev, Global Head of Operations, Datwyler Pharmaceutical Packaging

Photo Credit: Rahul Dev, Global Head of Operations

The rise in chronic diseases and the need for secondary devices over the last ten years has driven demand for more advanced and customized packaging solutions. This scenario also called for more stringent manufacturing models catering to the sensitivities of large molecule drugs. Rahul Dev, Global Head of Operations, Datwyler Pharmaceutical Packaging, provided further insights on the supply of biomedical assets consumables, including vaccine to meet global need.

What are the strategic approaches at Datwyler Healthcare to assist APAC region with COVID-19 vaccines and therapies?

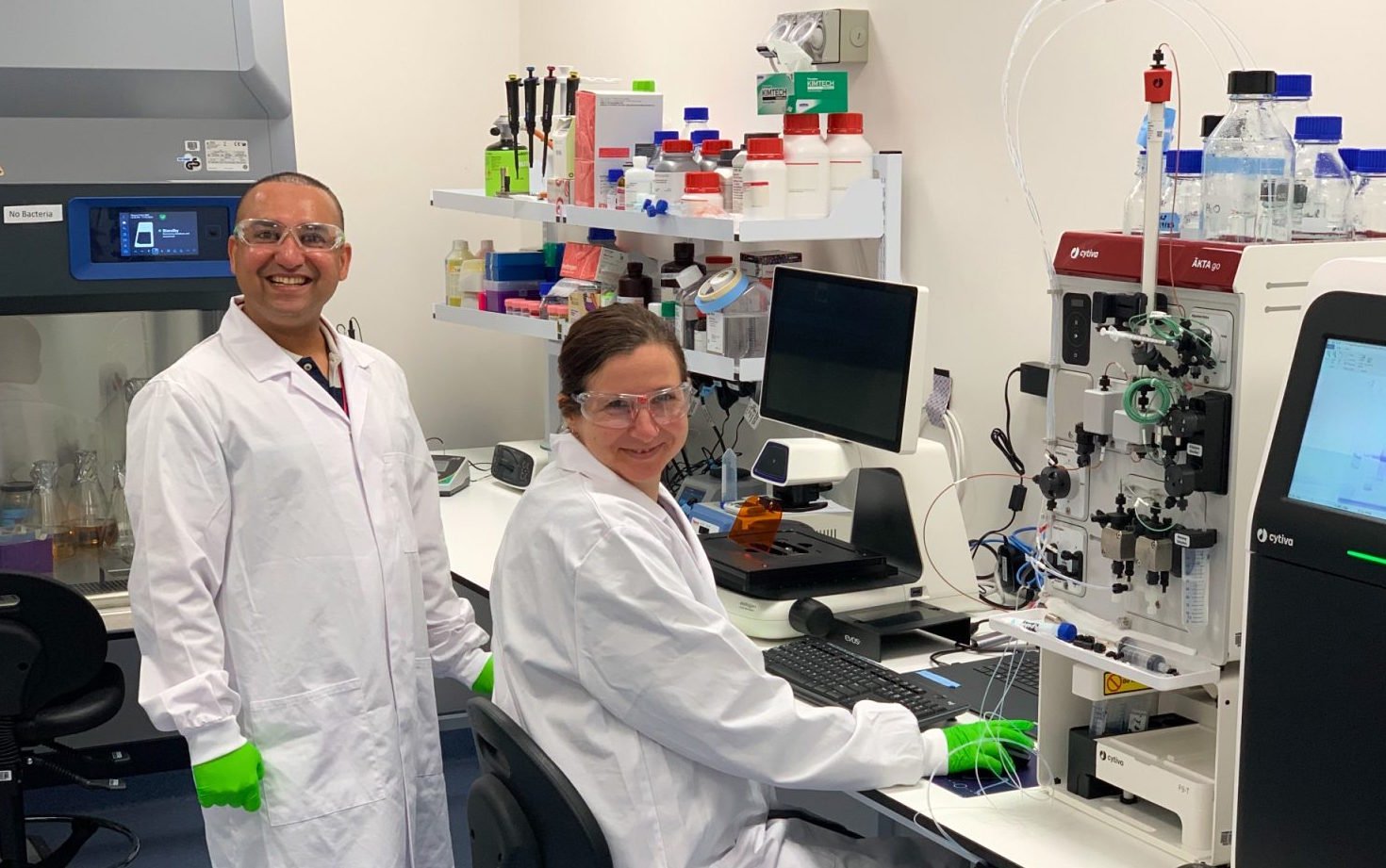

As a Swiss-based, leading supplier of elastomer-based components for the primary packaging of parenteral drugs, Datwyler is driven by a dedicated team, commitment to quality, and more than 100 years of experience. From our FirstLine™ facility in Kesurdi, India, we are supplying the most reputable biotech companies, including India-based injectable drug manufacturers, with components such as stoppers and plungers for vials, cartridges, and pre-filled syringes. Our India plant is a cornerstone of our strategic global production footprint to guarantee identical quality standards worldwide, allowing for supply chain flexibility, continuity, and risk mitigation. India, in particular, represents a critical market for pharmaceutical innovation, so it made sense for Datwyler to put down roots in Kesurdi back in 2010 to build a long-term relationship with this region. Beyond supporting our drug manufacturers in India, our facility supplies customers worldwide. In 2018, the Kesurdi facility became Datwyler’s largest plant by volume. As a result, we are expanding with the addition to our Advanced Standard facility in Pune, India, which is a proven and reliable solution for small molecule drugs. This facility is targeted to be ready in 2021.

Can you elaborate on Datwyler's novel manufacturing capabilities to prepare for the uninterrupted ancillary supplies to COVID-19 vaccine

Since the onset of COVID-19, Datwyler has supported several drug manufacturers working toward a vaccine. Our strategy is to manage demand bolstered not just by recent additions to our network of facilities and speeding the scale-up of our U.S. FirstLine facility, but also in balancing of capacity between COVID-19-related demands and supply for other important medicines. As vaccine-related demand ramps up, other needs ramp down, such as components for elective procedures. We redirect that capacity as needed. Our India plant extension coming online soon and we’ll be even better positioned to accommodate the influx in demand due to COVID-19. With the introduction of our newest FirstLine™ facility in the U.S., Datwyler is well-positioned to address the needs of the pandemic.

How is Datwyler responding to a sudden surge in demand in response to public health emergencies?

In addition to the facility expansion in India, we have scaled up FirstLine™ facility in Middletown, Delaware, USA at a faster pace than originally planned and ramped up production with a 24/7 schedule where we already have the infrastructure to add equipment to increase output. This has allowed us to increase capacity for coated components by almost 50 percent over the last two years and have more investments to optimize the use of our production facilities in the pipeline. Our special global supply team is ensuring readiness for COVID-19, but also enable continued production of sealing solutions for injectable drug packaging used in other medicines. We have been working concurrently with vaccine developers to determine the best solutions for each vaccine candidate and are providing solutions in a range of sizes, compounds, and with additional treatments to ensure that each vaccine is free from contamination and meets all compatibility and functional requirements for drug delivery. We are working in a strategic, collaborative process to understand the concerns and challenges that suppliers in India may have and are using our proprietary technology to help mitigate risk.