Rockwell Automation Saves Costs, Simplifies Sizing with New Servo System

18 November 2019 | News

Allen-Bradley Kinetix 5100 servo drive can run without a controller to meet a range of clinical and laboratory performance needs

Kinetix 5100

The growing consumer desire for more product variety and packaging sizes is creating a need for smaller, more flexible machines. To provide a more cost-effective option for OEMs building smaller machines, Rockwell Automation is introducing a new Kinetix 5100 servo drive, Kinetix TLP motor and cable that can function as a system without a controller.

The new Allen-Bradley Kinetix 5100 servo drive has multiple control modes available to support a wider range of high-speed, low-power motion control applications. The drive can be used with a Micro800 controller, a Logix controller or even by itself, allowing OEMs to choose how the product best functions in their applications.

“The Kinetix 5100 servo system works especially well for small- to mid-sized packaging machines that need cost-effective servo control,” said Simon Wong, product manager, Rockwell Automation. “Bundling the drive, motor and cable together create more competitive system pricing. And the ability for OEMs to select the products based on a machine’s power ratings can save time and effort – and help them get to market faster. This approach and product portfolio positions Rockwell Automation to accelerate our growth in China and emerging markets.”

The Kinetix 5100 servo system can also help OEMs make customers more productive. With the explosion of SKUs, manufacturers are faced with multiple changeovers, which are often a manual process. Using the Kinetix 5100 servo drive, OEMs can create a motorized or automated, system that can help speed up changeovers.

Additionally, with built-in safe torque off, users can remove motor torque without removing power from an entire machine, allowing a machine to restart faster after it has reached a safe state. Dual-port EtherNet/IP also supports device-level ring topologies.

The Kinetix 5100 servo drive provides an easy migration option for users of the Allen-Bradley Ultra 3000 digital servo drive. That system will soon be phased out in favour of the Kinetix 5100 servo drive.

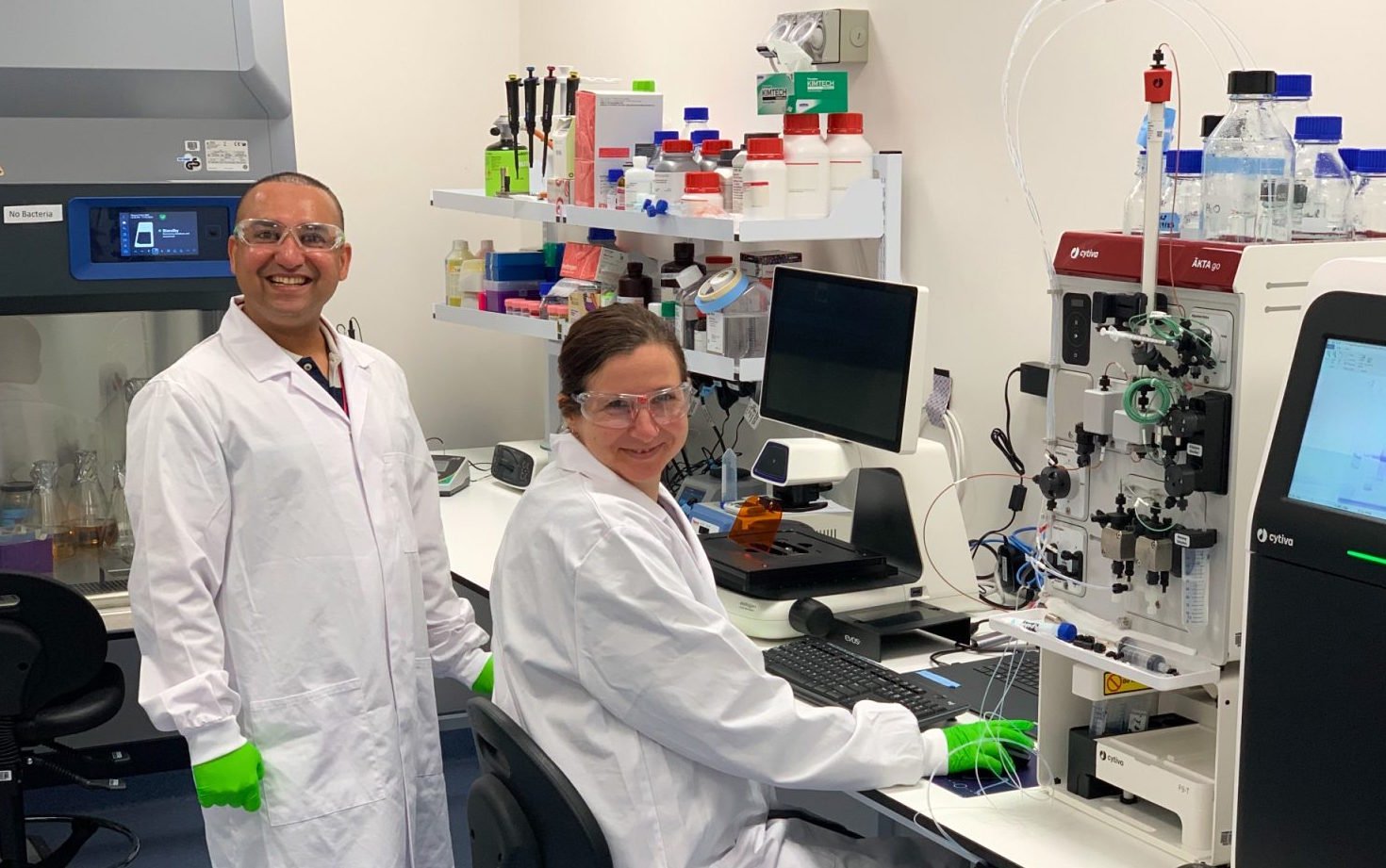

“In today’s demanding, consumer-driven environment that companies across the Asia Pacific are operating in, agile and flexible production capabilities are key to business competitiveness,” said Michael Vlahos, Business Manager, Motion. “We’re extremely pleased to introduce the Kinetix 5100 servo system to our customers, built specifically to increase efficiencies and enable variety so companies can meet the demand for more customized product solutions head-on.”